Packaging Waste Regulation (PPWR) –

packaging material and design between local recycling and global marketing.

New EU packaging regulations and innovative coating technologies are reshaping the industry's approach to sustainability, as manufacturers race to meet ambitious waste reduction targets while maintaining product protection standards.

The EU has introduced significant changes to packaging regulations, most notably the requirement for "tethered caps" on single-use drink containers up to three liters since July 2024. This initiative addresses the growing environmental concern of plastic waste, particularly from detached bottle caps that harm marine ecosystems. Research along Germany's North Sea coast revealed more than forty caps per hundred meters of beach, highlighting the scale of the problem. In spring 2024, the EU introduced the new Packaging and Packaging Waste Regulation (PPWR), aiming to combat the staggering 177 kilograms of packaging waste produced annually per EU citizen. The regulation targets a 15% reduction by 2040 through various measures, including bans on certain single-use packaging and stricter recyclability requirements for plastic packaging.

FLEXIBLE PACKAGING –

the ultimate answer

The industry has made significant strides in developing more sustainable packaging solutions, with coatings playing a crucial role. Dr. Andrey Charkovskiy from Siegwerk explains how modern coatings have evolved beyond simple print protection to provide comprehensive barriers against environmental factors like UV rays, oxygen, and heat. Unlike traditional multilayer materials, these innovative coatings can be easily recycled with monomaterials or washed off during processing. The focus has shifted to using monomaterials - homogeneous raw materials such as pure polyethylene (PE) or polypropylene (PP) - to improve recyclability. While this approach initially presented challenges in maintaining packaging functionality, new coating technologies have emerged to ensure proper protection while enhancing recycling potential.

THINKING THINGS THROUGH TO THE END –

and re-designing

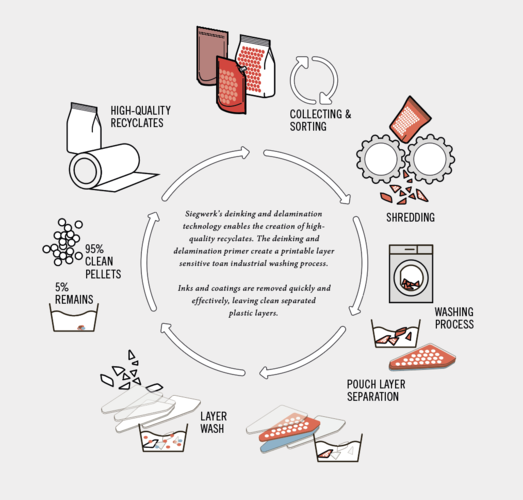

The industry is actively working to increase packaging recyclability through innovative solutions. A breakthrough in de-inking processes now allows printed materials to be effectively cleaned at 60-80 degrees Celsius in alkaline water. Siegwerk has developed de-inking de-lamination primers that enable the removal of previously stubborn inks from reverse-printed laminates. To standardize these advances, a consortium of manufacturers has established a test method for de-inking (DIN SPEC 91496). This initiative aims to build trust in new inking and coating technologies while providing a framework for industry-wide adoption. Companies implementing these sustainable approaches can benefit from reduced extended producer responsibility (EPR) charges while strengthening their brand's environmental credentials. The future of packaging hinges on balancing sustainability with functionality, as the industry works to meet both regulatory requirements and growing consumer demand for environmentally responsible solutions. These innovations in flexible packaging and recycling technologies represent significant steps toward a more sustainable packaging industry.

PACKAGING SUSTAINABILITY MANAGEMENT –

all in one

As a result of the new EU packaging and packaging waste directive, the European Commission also needs to develop a method in the short term to compare the recycling regulations of other countries with those of the EU. After all, trade partners outside the EU will likewise have to adhere to the requirement to recycle a large part of their plastic packaging in line with EU regulations. Companies are now faced with public, financial and legal pressure to achieve recycling quotas for their packaging.

However, despite good prospects for future harmonisation within Europe, the present situation remains a patchwork of different approaches to recycling. Therefore, the recyclability of packaging cannot be measured purely in terms of its material; rather, country-specific legislation and waste management systems are an important factor. Seeking clarity, software developer Recyda has come up with an app. Their tool allows companies to check their packaging portfolio for compliance with different national regulations and standards. Both they and other users can access the information in a database.